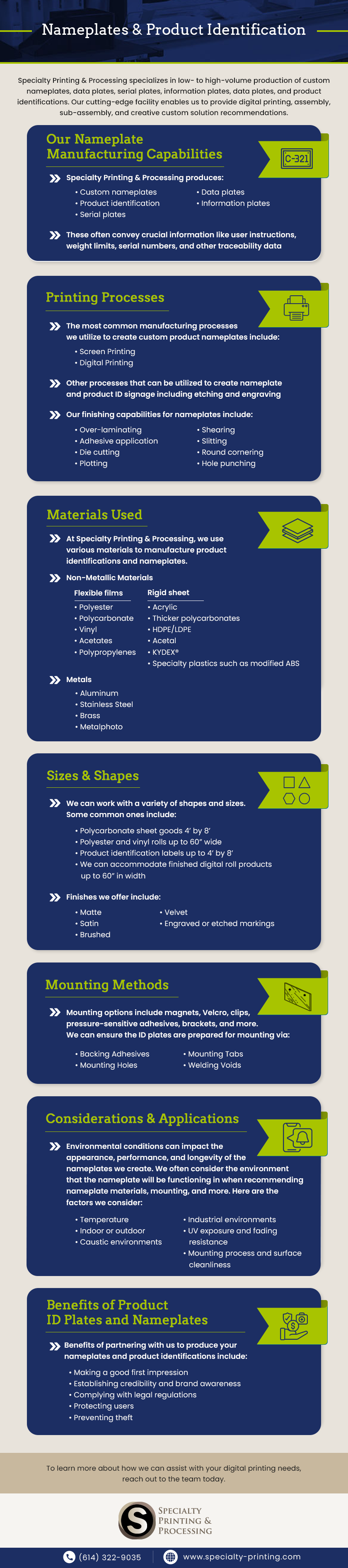

Nameplates & Product Identification

Specialty Printing & Processing specializes in low- to high-volume production of custom nameplates, data plates, serial plates, information plates, data plates, and product identifications. Our cutting-edge facility enables us to provide digital printing, assembly, sub-assembly, and creative custom solution recommendations.

Not sure what you need? Our award-winning team has over 100 years of combined experience manufacturing nameplates and product identification; we offer industrial engineering services to ensure your design makes it onto the product and stays there. Get connected with our team of experts today.

Our Nameplate Manufacturing Capabilities

Specialty Printing & Processing produces:

- Custom nameplates

- Product identification

- Serial plates

- Data plates

- Information plates

These often convey crucial information like user instructions, weight limits, serial numbers, and other traceability data.

Printing Processes

The most common manufacturing processes we utilize to create custom product nameplates include:

- Screen Printing: Screen printing involves using a mesh screen to transfer ink onto the nameplate. We have four different types of screen printing equipment that can create high-quality, durable results.

- Digital Printing: Digital printing uses digital files to print directly onto the desired materials. By eliminating many of the mechanical steps required by traditional printing techniques, this modern printing method drastically reduces setup time. With just a computer and a printer, digital printing can produce high-quality, high-resolution images quickly.

Other processes that can be utilized to create nameplates and product ID signage include etching and engraving.

Our finishing capabilities for nameplates include:

- Over-laminating

- Adhesive application

- Die cutting

- Plotting

- Shearing

- Slitting

- Round cornering

- Hole punching

Materials Used

At Specialty Printing & Processing, we use various materials to manufacture product identifications and nameplates.

Non-Metallic Materials:

- Flexible films

- Polyester

- Polycarbonate

- Vinyl

- Acetates

- Polypropylenes

- Rigid sheet

- Acrylic

- Thicker polycarbonates

- HDPE/LDPE

- Acetal

- KYDEX

- Specialty plastics such as modified ABS

Metals:

- Aluminum: This is a cost-effective and versatile nameplate material. Aluminum is durable, lightweight, corrosion-resistant, and allows for clean and clear presentation in any color.

- Stainless Steel: Stainless steel nameplates offer durability, antimicrobial properties, superior corrosion resistance, and high-quality graphics.

- Brass: Brass is a durable material with excellent weather resistance properties. It also has a unique, lustrous color that lends itself well to decorative and industrial applications.

- Metalphoto: This long-lasting material offers an impenetrable surface that can withstand abrasion, sunlight, and heat. These properties make metalphoto ideal for military, aerospace, and other outdoor heavy-duty applications. This material can provide up to 20-year outdoor life.

Sizes & Shapes

We can work with a variety of shapes and sizes. Some common ones include:

- Polycarbonate sheet goods 4’ by 8’

- Polyester and vinyl rolls up to 60” wide webs

- Product identification labels up to 4’ by 8’

- We can accommodate finished digital roll products up to 60” in width

Finishes we offer include matte, satin, brushed, velvet, and engraved or etched markings. Our M&R and American Cameo screen printers can create a variety of nameplate and product identification designs. We also have a full line of digital printing equipment, including Mimaki, Epson, Gerber, and HP systems.

Mounting Methods

Mounting options include magnets, Velcro, clips, pressure-sensitive adhesives, brackets, and more. We can ensure the ID plates are prepared for mounting via:

- Backing Adhesives: Once the nameplates have been marked, they have to be attached to the product surface. Specialty Printing & Processing offers durable and reliable adhesive backing options, including a wide selection of 3M® adhesives with waterproof properties, UV resistance, solvent resistance, and high- and low-temperature resistance. These can be applicable for low or high-surface energy substrates. We also offer General Formulations, FLEXcon, and Avery nameplate adhesives.

- Factors that determine the best choice of adhesive include application and environment, surface texture, surface material, surface energy, and weight. Adhesives are pressure-sensitive, solvent-activated, or thermal-activated. Our team can help you select the right adhesives to fit your specific needs.

- Products can be manufactured with tabs or slits to allow ease of application.

- Mounting Holes: Mounting holes accommodate screws, bolts, fasteners, drive screws, and rivets.

- Mounting Tabs: Mounting tabs facilitate mechanical attachment.

- Welding Voids: We can accommodate and design void areas within the part to facilitate welding as a mounting option.

Considerations & Applications

Environmental conditions can impact the appearance, performance, and longevity of the nameplates we create. We often consider the environment that the nameplate will be functioning in when recommending nameplate materials, mounting, and more. Here are the factors we consider:

- Temperature

- Indoor or outdoor

- Caustic environments

- Industrial environments

- UV exposure and fading resistance

- Mounting process and surface cleanliness

Benefits of Product ID Plates and Nameplates

Benefits of partnering with us to produce your nameplates and product identifications include:

- Making a good first impression: Brands only have a few seconds to capture a prospective buyer’s interest. A visually appealing product identification label can introduce the product to them in a positive light, making a great first impression.

- Establishing credibility and brand awareness: Nameplates help differentiate your products from others on the market. A properly placed and designed nameplate can promote brand awareness and build credibility among consumers.

- Complying with legal regulations: Product identifications are often required by law to inform users how to use a certain product. Designing and printing high-quality labels can keep your company in full legal compliance.

- Protecting users: Nameplates and product identification can help ensure the safety of your customers by communicating all necessary product information about safe and correct use.

- Preventing theft: Permanently attached nameplates make products traceable and can guard against counterfeiting and theft.

Custom Nameplates From Specialty Printing & Processing

Nameplates and product identification play a vital role in helping companies keep track of their products, prevent theft, differentiate their products from competitors, and increase brand awareness while conveying important information to customers.

If you need custom nameplates or product identifications, our team is ready to help. We provide high-quality nameplates and product identification services as well as a wide range of value-added services to meet your unique printing and processing needs. For more information about our capabilities, contact us today or request a consultation.